Cable Tray

- by Admin

- Comts 02

Electric Power Engineering in Pakistan

Electric Power Engineering (EPE) is a leading manufacturer of cable trays in Pakistan. Known for their high-quality products and exceptional customer service, EPE has established itself as a trusted name in the electrical engineering industry. They provide solutions that meet international standards, ensuring safety and efficiency in electrical installations. This article will explore the benefits and advantages of using cable trays, the different types available, and the materials they are made from. Additionally, we will highlight EPE's presence in various cities across Pakistan, including Lahore, Faisalabad, Karachi, and Islamabad.

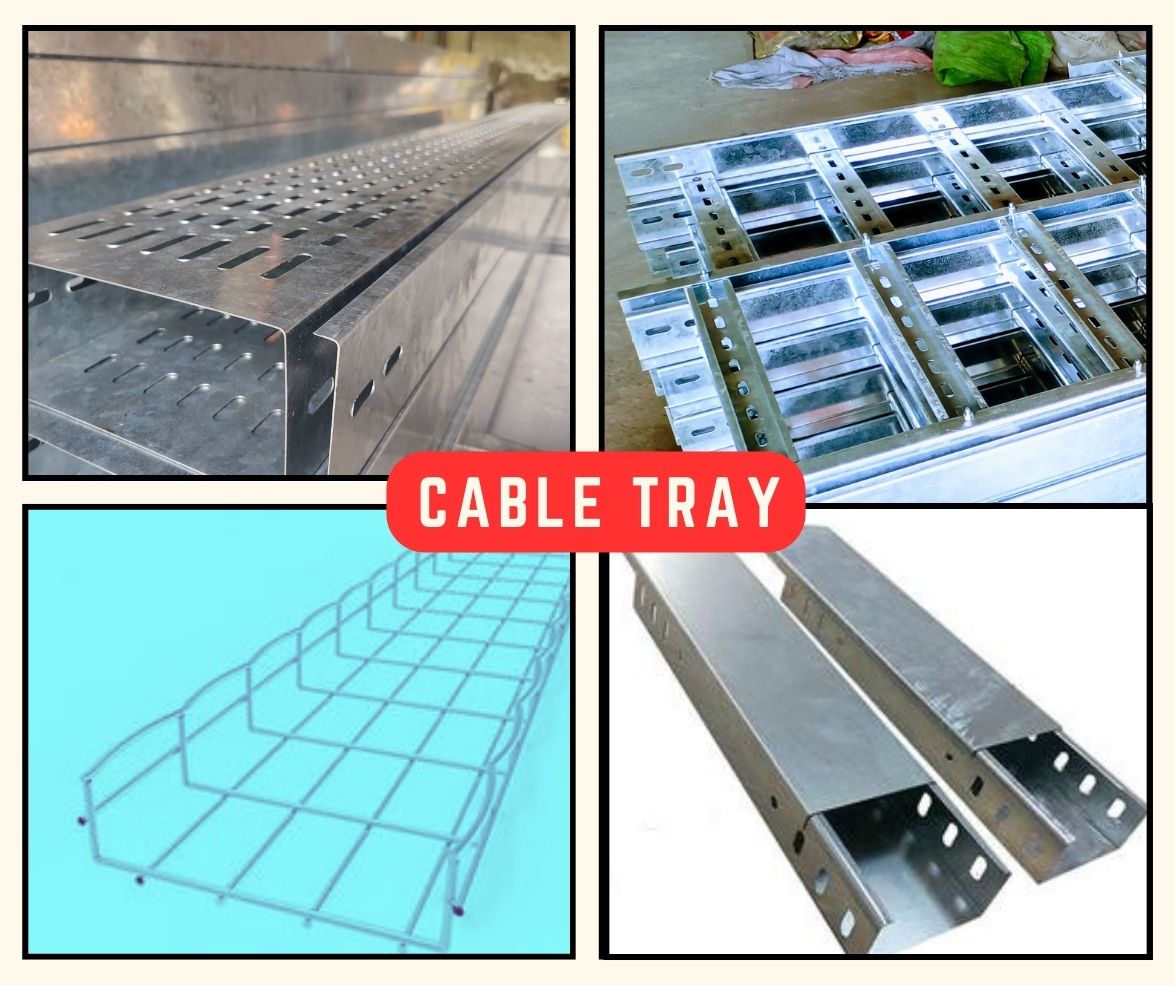

What is cable tray

A cable tray is a structural system used to support and organize electrical cables, wires, and conduits in various settings, including industrial, commercial, and residential environments. Made from materials such as steel, aluminum, or fiberglass, cable trays provide a safe, reliable pathway for electrical wiring and help in maintaining a neat, organized, and accessible setup. They are particularly useful for routing cables over long distances, around obstacles, and through complex infrastructure.

Benefits and Advantages of Cable Trays

Cable trays are an essential component in modern electrical systems, providing several benefits:

1. Organization and Safety

Cable trays help in organizing and managing cables, preventing tangled wires and reducing the risk of electrical hazards. This organized setup ensures that maintenance and troubleshooting are more straightforward and safer.

2. Durability

Made from robust materials, cable trays are designed to withstand harsh environmental conditions, ensuring long-term durability and reliability.

3. Ease of Installation and Maintenance

Cable trays are relatively easy to install, requiring less time and effort compared to other wiring systems. Their design also facilitates easy access for maintenance and repairs, minimizing downtime.

4. Cost-Effective

Using cable trays can be more cost-effective in the long run due to their durability and the reduced need for frequent replacements or repairs. They also save money on labor costs due to their easy installation process.

5. Scalability

Cable trays offer excellent scalability, allowing for the addition of new cables without significant modifications to the existing setup. This flexibility is particularly beneficial for growing businesses and expanding infrastructures.

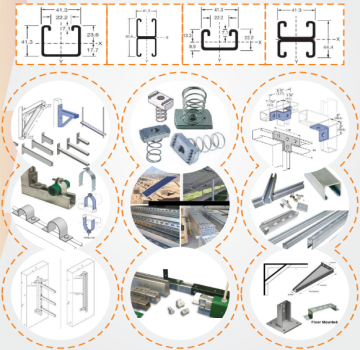

Types of Cable Trays

There are several types of cable trays available, each designed to meet specific needs:

1. Perforated Cable Tray

A perforated cable tray is a type of cable management system that features a series of holes or slots along its base and sides. These perforations provide several advantages: they allow for better air circulation around the cables, which helps prevent overheating; they enable easier attachment of cables using ties or other fasteners; and they facilitate drainage in areas prone to moisture.

2. Ladder Cable Tray

Ladder cable trays are the most common type, characterized by their two side rails connected by cross rungs. They provide excellent ventilation for cables, reducing heat buildup.

3. Solid Bottom Cable Tray

These trays have a solid base, offering maximum protection to the cables from dust and other contaminants. They are ideal for environments where cable protection is a priority.

4. Through Cable Tray

Trough cable trays have a ventilated bottom and solid side rails, providing a balance between protection and ventilation. They are suitable for a variety of applications.

5. Channel Cable Tray

Channel cable trays are used for smaller cable runs and are often utilized in light industrial and commercial settings.

6. Wire Mesh Cable Tray

These trays are made from a wire mesh material, offering high flexibility and ease of installation. They are commonly used for telecommunication and fiber optic cables.

Material of Cable Trays

Cable trays are made from various materials, each offering different benefits:

1. Steel

Steel cable trays are known for their strength and durability. They are often galvanized to prevent corrosion, making them suitable for outdoor and industrial applications.

2. Aluminum

Aluminum cable trays are lightweight yet strong, offering excellent resistance to corrosion. They are ideal for installations where weight is a concern.

3. Stainless Steel

Stainless steel trays provide superior corrosion resistance and are used in harsh environments where exposure to chemicals and moisture is a concern.

Cable Tray in Lahore

Electric Power Engineering has a significant presence in Lahore, providing high-quality cable trays to various industries. Their products are widely used in commercial buildings, industrial plants, and residential complexes. The availability of different types and materials of cable trays ensures that customers in Lahore can find the perfect solution for their needs.

Cable Tray in Faisalabad

In Faisalabad, EPE's cable trays are essential for the city's thriving textile and manufacturing industries. The durability and reliability of their products make them a preferred choice for many businesses. EPE's focus on quality ensures that their cable trays can withstand the demanding conditions of industrial environments.

Cable Tray in Karachi

Karachi, being the economic hub of Pakistan, requires efficient and reliable electrical solutions. EPE's cable trays are widely used in Karachi's commercial and industrial sectors. The company's commitment to innovation and quality ensures that their cable trays meet the city's high standards and diverse requirements.

Cable Tray in Islamabad

Islamabad, the capital city, has a growing demand for modern electrical infrastructure. EPE provides top-notch cable trays that cater to the city's expanding needs. Whether it's for government buildings, commercial projects, or residential developments, EPE's cable trays offer the perfect blend of functionality and durability.

In conclusion, Electric Power Engineering stands out as a premier cable tray manufacturer in Pakistan, offering a wide range of high-quality products to meet the diverse needs of their customers. Their presence in Lahore, Faisalabad, Karachi, and Islamabad ensures that they can provide reliable and efficient solutions across the country. If you are looking for a cable tray manufacturer in Pakistan, EPE is the go-to choice for quality and excellence.